Experience

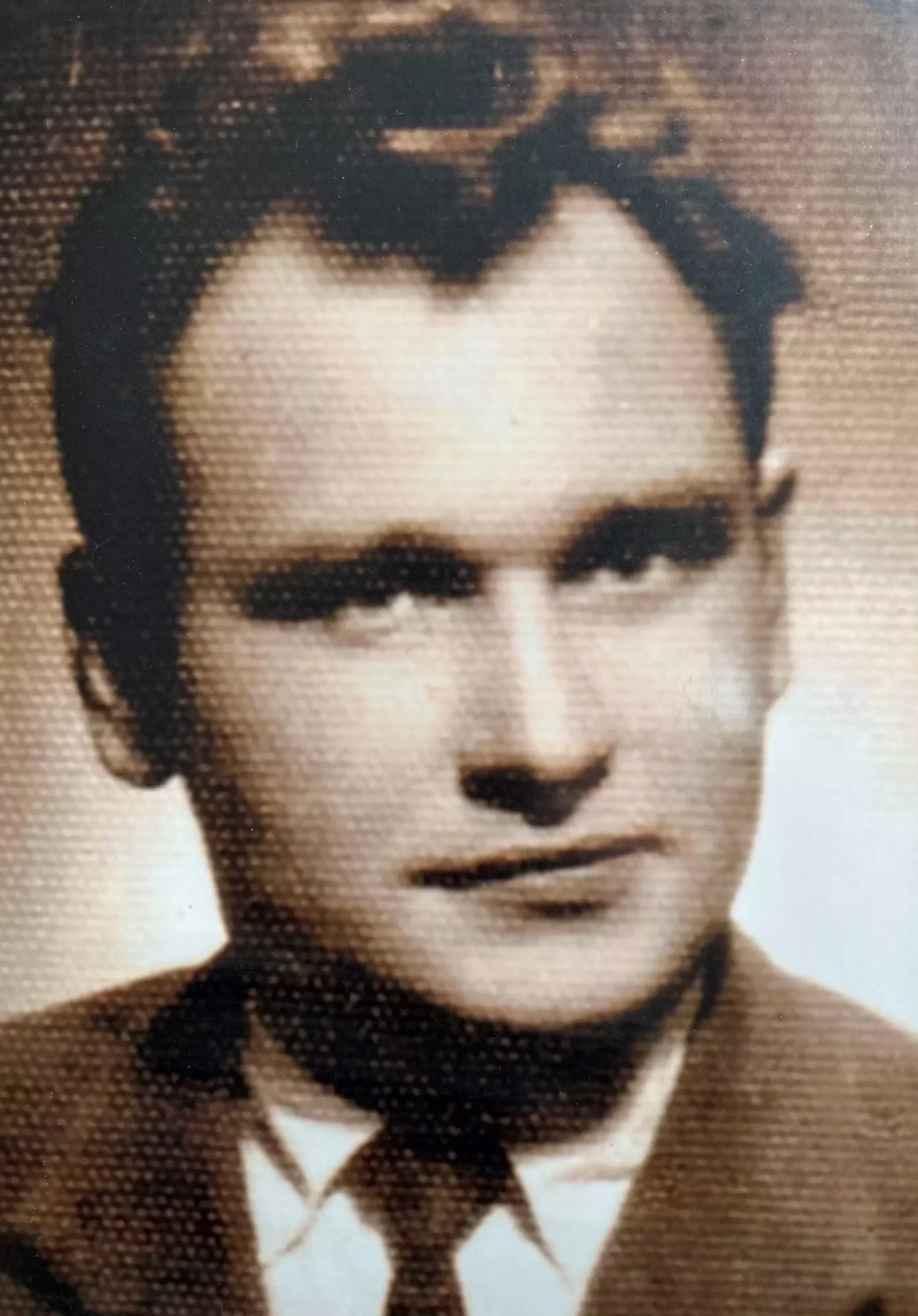

We have 50 years of experience in the industry!

Polish production

Our products are 100% made in Poland

Quality control

We offer the highest quality products

HML Nosewicz

Stainless steel tank manufacturer – the highest quality stainless steel devices

We design and manufacture devices made of stainless steel with the highest quality standards. We are able to meet the wide requirements of customers

in terms of pressure, temperature or volume. Our products are used in such areas as the energy, chemical, pharmaceutical, cosmetic and food industries.

The main products of HML Nosewicz are: mixers, stirrers, process tanks, heat exchangers, storage tanks, pharmaceutical tanks, columns (absorption, distillation, rectification), pipelines, skid system, anti-pulsation cylinders, separators, filter housings, quick openings closure), rotary dryers.

HML Nosewicz in numbers

years of experience

tanks produced

distinctions and awards

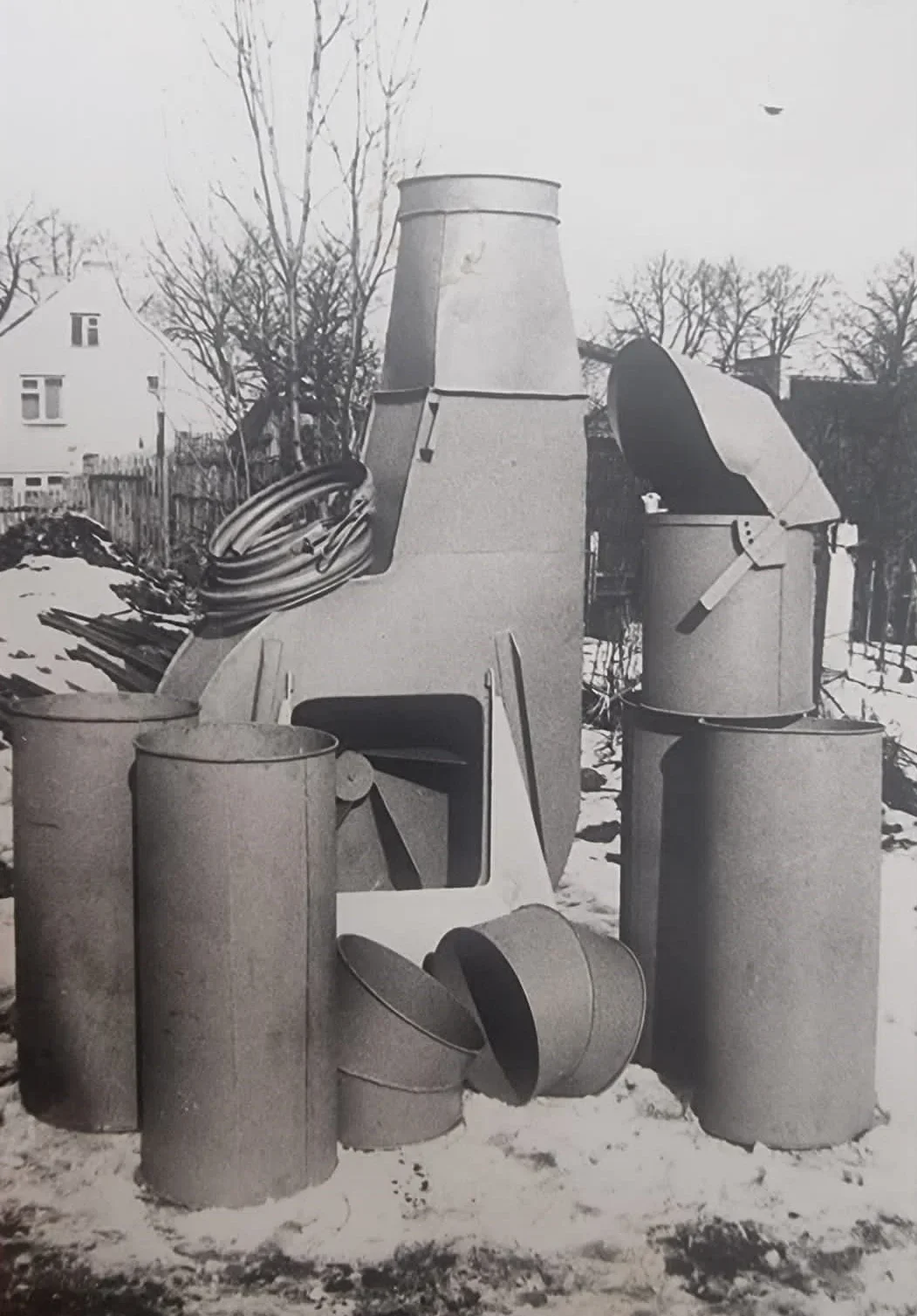

Our History

HML Nosewicz is a family company based on values

HML NOSEWICZ is primarily a family business with a long tradition, whose management model is based on 5 basic elements:

⦁ Mission

⦁ Vision

⦁ Strategy

⦁ Organizational culture

⦁ Values

The HML NOSEWICZ company is developing very dynamically, transforming from a small, local enterprise into a global company able to meet the most restrictive customer requirements. HML NOSEWICZ was founded by Henryk Nosewicz in 1970. In the period from 1990 to 2013, the company was managed by Mirosław and Leszek Nosewicz. Currently, Bartosz and Michał Nosewicz play the management role.

Our values

In the production process, we use not only the knowledge and experience of our employees, but also many modern, precise machines, devices and tools. Such as modern automatic welding machines and CNC systems, ensuring the highest quality and precision of workmanship.

1

Highest quality

Our goal is to meet the highest quality standards so that we can meet the most stringent customer requirements. We are constantly striving to improve quality. We implement this strategy by implementing the ISO 9001:2015 standard and its continuous development.

2

A team of employees

Our development is not only new halls, machines or devices. Our development is primarily the development of our employees: engineers, welders, locksmiths, operators and other high-class specialists supporting production. We invest in their knowledge and skills through training and challenges.

3

Trust

Trust is the basis of our relations with customers, we make sure that our products comply with customer requirements and standards applicable in specific cases. Each element used in production is fully traceable and has the required certificates.

4

Development

Continuous improvement and change are a key element to meet the constantly changing needs of our customers, legal regulations and security requirements.

Production possibilities

Get to know our production capabilities and check what we can offer your company.

Cutting steel

Water Jet: 3000x6000mm / up to 120mm

Plasma: 2500x4500mm / up to 120mm

Bending

Half tubes and coiled half tubes

Internal coil

Flat heating coil

C-Profiles heating coil

Welding

Welding processes:

TIG (141, 142),

MAG (135, 136),

SAW (121),

plasma (151)

Rolling

Rolling of sheets up to 35mm thick and 4500mm in diameter.

Bottom formation

Conical bottom

Flat bottom

Polishing

Shell grinding up to Ra 0.01 / mirror up to 5000mm long

Bottom grinding up to Ra 0.01 / diameter 3500mm depth 1400mm.

Mechanical treatment

Machining of tanks and bottoms up to 2000 mm in diameter and 6000 mm in length.

Materials

Carbon steel: Group 1.1, Group 1.2 PN-EN ISO 15614

Stainless steel: Group 8.1, SMO PN-EN ISO 15614

Duplex / Super duplex: Group 10.1 , Group 10.2 EN ISO 15614

More

Familiarize yourself with our offer and learn about our full production capabilities

Contact

Stainless steel tank manufacturer – HML Nosewicz

The production of stainless steel tanks is an extremely important area of industry that plays a crucial role in storing and transporting various substances. Stainless steel, thanks to its unique properties, is a material perfectly suited for this purpose, offering durability, corrosion resistance, and ease of hygiene maintenance.

The process of producing stainless steel tanks begins with careful design. Engineers take into account all parameters such as capacity, pressure, temperature, and the type of substances to be stored. The design must also comply with all safety standards and regulations as well as industrial standards. Then the process of cutting and shaping stainless steel sheets begins. Advanced technologies, such as laser cutting, allow for the creation of precise components, which are then joined to create the tank body. Welds are carefully executed to ensure the durability and integrity of the structure.

After assembling the body, surface treatment is carried out. Stainless steel can be ground or polished, not only improving aesthetics but also providing protection against corrosion. Additionally, tanks can be equipped with thermal insulation to maintain a stable temperature inside.

The next step is the installation of additional elements such as valves, pressure gauges, or monitoring systems. Depending on the tank’s purpose, various accessories may be applied, tailored to the specific nature of the stored substances. The entire process of producing stainless steel tanks is subject to strict quality controls to ensure that the finished product meets all standards and customer expectations. These tanks find applications in various industries such as chemical, food, pharmaceutical, or energy, where reliability and durability are key criteria.

It is worth emphasizing that the production of stainless steel tanks not only contributes to efficient resource management but also serves as a significant element of environmental care. Stainless steel is largely recyclable, reducing its negative impact on the natural environment.

Stainless Steel Tanks – Production by HML Nosewicz

Stainless steel tanks are an essential component in many industrial sectors. HML Nosewicz is a renowned manufacturer specializing in producing high-quality tanks for various industrial applications. The tank production process at HML Nosewicz is carefully monitored at every stage. Only the highest quality materials are used, ensuring durability and safety in use. Engineers at HML Nosewicz ensure precision in every detail of the tank, guaranteeing its functionality and aesthetic appearance. Thanks to modern production technologies, the tanks meet the highest quality standards. Commissioning tank production at HML Nosewicz is a decision to collaborate with an experienced partner who can meet even the most demanding customer expectations. Safety, reliability, and professionalism are the values that distinguish HML Nosewicz products in the industrial market.