Quality Control – HML Nosewicz

At HML Nosewicz, we operate in full compliance with applicable legal regulations and standards governing the production, design, and assembly of pressure equipment.

We meet the highest quality standards, confirmed by the following certifications:

– ISO 9001:2015

– ISO 3834-2:2005

– ASME Sec VIII Div. 1 – 2021 – U-Stamp

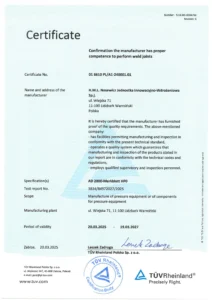

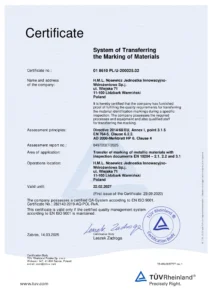

We have established long-term cooperation with notified bodies such as the Office of Technical Inspection (UDT) and TÜV, from which we have obtained certificates of conformity for the production of pressure equipment. These certificates comply with the Pressure Equipment Directive PED/2014/68/EU within the following scopes:

– Module A2 (Internal production control and supervised pressure equipment checks at random intervals)

– Module G (Conformity based on unit verification)

– Module H (Conformity based on full quality assurance)

– Module H1 (Conformity based on full quality assurance and design examination)

The above documents confirm that our company and the products we manufacture meet the standards applicable within the European Union.

The Quality Control Department supervises every stage of the process, starting from the inspection of supplied components and materials, through individual production stages, required tests and pressure trials, and final acceptance with the client (either in a traditional form or remotely using holographic equipment), up to the delivery of the finished product. After completion of testing phases, the client receives full as-built documentation.

The company ensures a high level of workmanship at every stage of production.

Our highly qualified and certified personnel perform VT2 and PT2 weld inspections in accordance with PN-EN ISO 17635. For other non-destructive testing (NDT), thanks to long-standing cooperation with experienced specialized companies, we also carry out inspections such as RT, UT, MT, FT, PMI, as well as a range of destructive testing (DT) methods.

Welding processes are supervised by personnel holding the International Welding Engineer (IWE) diploma, authorizing them to perform key functions in accordance with EN ISO 14731.

During inspections, we use top-class measuring instruments that allow us to verify the accuracy of our components with high precision. Our products are inspected in accordance with execution standards and all additional customer requirements.

We place particular emphasis on close cooperation with the client to deliver a fully satisfactory product—customer satisfaction is our top priority.

Our certificates

- ISO 9001 282143 2019 AQ POL RvA 3 en US 20241220 1

- ISO 3834 2 Rev. 3.0 ENG Final 20250211 1

- SELO 19.02.2025 18.02.2029 1

- Certyfikat Mod. H1 EN 2025 2028 1

- Certyfikat EN 1090 ENG 03.2025 03.2026 2

- Certyfikat EN 1090 ENG 03.2025 03.2026 1

- Certyfikat AD2000 HP0 03.2025 02.2027 EN 1

- 107678 BPV CERT 01.12.26 RR 1

- 2026.09 A2 1

- Axpo

- System przenoszenia Oznaczeń Materiałowych 03.2025 02.2027 EN 1